Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

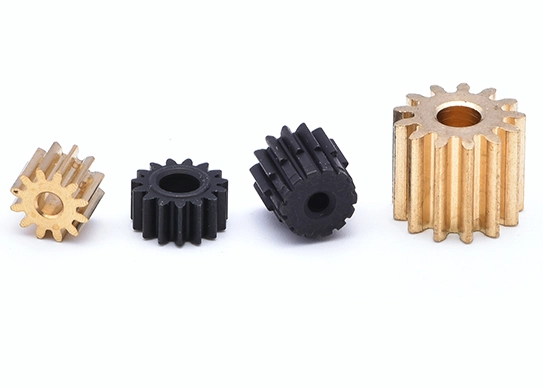

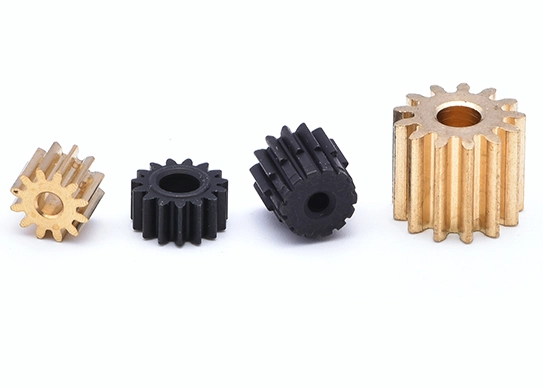

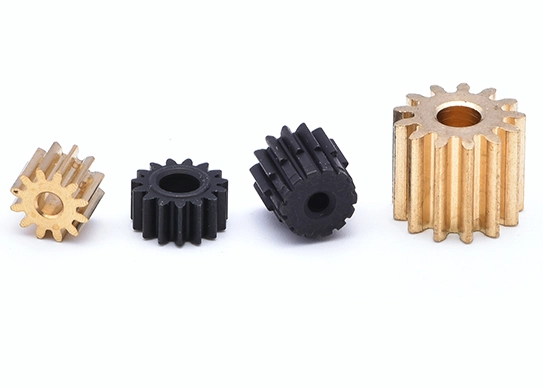

Gears are fundamental mechanical components used to transmit torque and convert rotational motion between intersecting shafts. They can adjust the direction of rotation, change the speed of rotation, and vary the torque or power transmitted to another part. Made from a variety of materials, including metals and plastics, gears are precision-engineered to ensure smooth operation and durability under load. The teeth of a gear are meticulously shaped to mesh smoothly and efficiently with other gears, minimizing wear and maximizing efficiency.

Automatic lathe machining gears are precision-engineered components designed for use in automated lathes, where accuracy and reliability are paramount. These gears are crafted with high-quality materials such as hardened steel or alloy metals to withstand the rigorous demands of continuous operation and ensure long-lasting performance. Their design incorporates precise tooth profiles and fine tolerances, which are crucial for maintaining smooth gear interactions and minimizing mechanical backlash.

The automatic lathe machining process allows for high-volume production with consistent quality, producing gears that fit seamlessly into automated systems. This method ensures that the gears maintain their geometric integrity and functionality even under high-speed or high-torque conditions. Ideal for applications in industrial machinery, automotive systems, and robotics, these gears facilitate efficient and reliable operation, reducing downtime and maintenance needs while enhancing overall system performance.

aaron18129983931@gmail.com

aaron18129983931@gmail.com

aaron18129983931@gmail.com