Aaron: +86-18129983931

Max: +86-18922922459

Micro Screws

Micro Screws

Big Head Screws

Big Head Screws

Construction Screws

Construction Screws

CNC Lathe Machining Parts

CNC Lathe Machining Parts

Cold Forged and Undergo Secondary Processing Products

Cold Forged and Undergo Secondary Processing Products

Multi Station Cold Heading Screws

Multi Station Cold Heading Screws

Step Screw

Step Screw

Automatic Lathe Machining Parts

Automatic Lathe Machining Parts

High Difficulty Challenge Cold Heading Fasteners

High Difficulty Challenge Cold Heading Fasteners

New Tech Fasteners

New Tech Fasteners

Machine Screws

Machine Screws

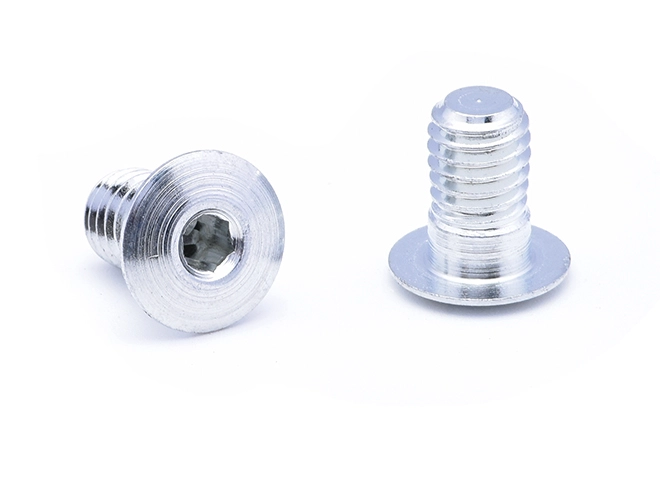

Socket Cap Screws

Socket Cap Screws

Hexagon Socket Set Screws

Hexagon Socket Set Screws

Pull Out Rivet

Pull Out Rivet

Self Tapping Screws

Self Tapping Screws

Hex Bolts

Hex Bolts

Self Drilling Screws

Self Drilling Screws

Eye Bolts

Eye Bolts

U-bolts

U-bolts

Threaded Sheath

Threaded Sheath

Hex Nut

Hex Nut

Hex Long Nut

Hex Long Nut

Pull Rivet Nut

Pull Rivet Nut

Square Nuts

Square Nuts

Combination Screws

Combination Screws

Pin

Pin

Nylon Locking Nuts

Nylon Locking Nuts

Pressure Rivet Nuts

Pressure Rivet Nuts

Cage Nut

Cage Nut

Welding Screws

Welding Screws

Butterfly Screw

Butterfly Screw

American Standard Butterfly Nut

American Standard Butterfly Nut

Expansion Screw

Expansion Screw

Plug Screw

Plug Screw

Stainless Steel Washer

Stainless Steel Washer

Double Overlap Anti-Loosening Washers

Double Overlap Anti-Loosening Washers

Waterproof and Anti-Drop Screws

Waterproof and Anti-Drop Screws

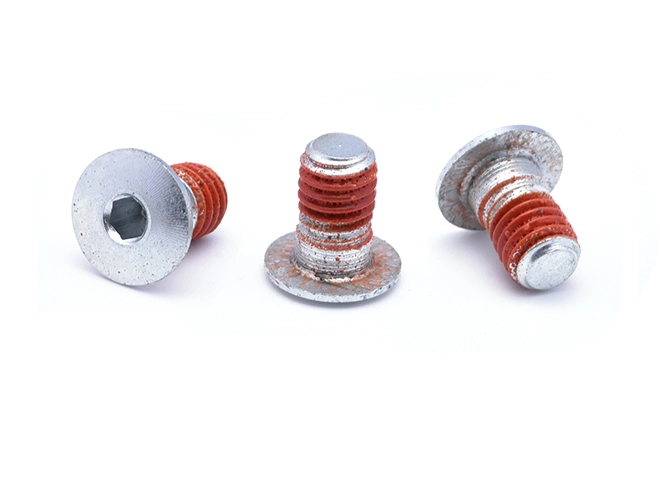

Super Corrosion-Resistant Screws

Super Corrosion-Resistant Screws

New Type Switchgear

New Type Switchgear

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Anti-loose Easy Disassembly Nut Pillar (New Furniture Connector)

Furniture Simple Assembly and Disassembly Connector

Furniture Simple Assembly and Disassembly Connector

Micro Vibration Absorber

Micro Vibration Absorber

65Mn Material Furniture Connector

65Mn Material Furniture Connector

Counter Table Base

Counter Table Base

Furniture Connector Nut with Plastic Sleeve

Furniture Connector Nut with Plastic Sleeve

Furniture Horizontal Hole Nut

Furniture Horizontal Hole Nut

Furniture Connecting Screw

Furniture Connecting Screw

Furniture Connecting Nut Seat

Furniture Connecting Nut Seat

Double Stack Wheels Used On Furniture

Double Stack Wheels Used On Furniture

Components Used On Furniture

Components Used On Furniture

Connection Buckle

Connection Buckle

Internal Hexagonal Spiral Screw

Internal Hexagonal Spiral Screw

Iron Colored Carbon Steel Four Claw Nut

Iron Colored Carbon Steel Four Claw Nut

Iron Furniture Three Combination Nut Seat

Iron Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Iron and Zinc Alloy Furniture Three Combination Nut Seat

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Gray Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Dowel Pin+ Transparent Elephant Rubber Sleeve

Injection Molded Furniture Foot Pad Screw

Injection Molded Furniture Foot Pad Screw

Automatic lathe machining parts, also known as CNC (Computer Numerical Control) lathes parts, are sophisticated machines used extensively in the manufacturing industry to produce precision parts from various materials. These machines operate automatically, controlled by pre-programmed sequences that guide tools to cut and shape the workpiece according to specified dimensions and designs.

Regular Maintenance: Keeping the machine in good working condition.

Quality Control: Implementing rigorous inspection processes, including dimensional checks and material testing.

Tooling: Using high-quality, sharp tools and replacing them as needed.

Programming: Ensuring the CNC programs are accurate and optimized.

Define Requirements: Determine dimensions, tolerances, and materials.

Create CAD Models: Design the part digitally.

Test Prototypes: Validate design feasibility.

Optimize for Production: Simplify designs for efficiency.

| Factor | Automatic Lathe | CNC Machining |

Volume | Best for high-volume (10,000+ units) | Ideal for low-mid volume (1–5,000 units) |

Tolerance | ±0.01mm (Swiss-type lathes) | ±0.005mm (5-axis CNC) |

Material | Metals (brass, aluminum, steel) | Metals, plastics, composites |

Lead Time | Faster for simple shapes | Longer for complex geometries |

Cost per Unit | Lower at scale | Higher for small batches |

Mass Production: Screws, pins, or bushings needing<30-second cycle times.

Simple Geometries: Round or hexagonal parts with minimal features.

Example: A automotive supplier produces 500,000 fuel injector pins monthly via Swiss lathes.

Complex Parts: Components with 3D contours, slots, or irregular shapes.

Prototyping: Test functional designs before mass production.

Example: A medical device company CNC-machines titanium bone screws with helical flutes.

Hybrid Approach

Combine both for cost efficiency:

Prototype: CNC machining for design validation.

Mass Produce: Automatic lathe for high-volume runs.

Cost-Saving Tip: Use automatic lathes for the shaft of a bolt and CNC for custom heads.

aaron18129983931@gmail.com

aaron18129983931@gmail.com

aaron18129983931@gmail.com